The Best Coupling Ever Built Has Arrived

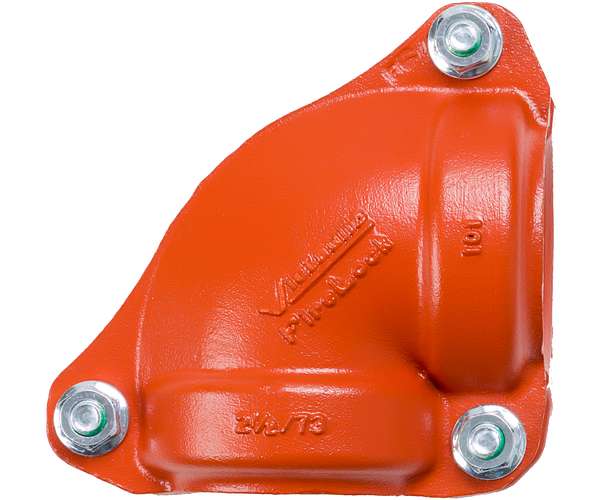

Introducing the new Style 107V Rigid Coupling and new QuickVic™ Fittings

The first and only coupling designed for high-performance impact guns with fabrication-friendly fittings that deliver unmatched productivity

Sustainability

Driving sustainability in our value chain, enabling circularity in construction.

LEARN MORE

PROJECT PARTNERSHIPS

Every day, on every project, we work for you. Your success is our mission.

EXPLORE OUR PROJECT PARTNERSHIPS

SUBMITTAL PACKAGE ENGINE

Now anyone can build a submittal package delivered as a single combined PDF file with a customizable cover sheet.

CREATE A PACKAGE

Sprinkler Catalog

Easily filter our industry-leading sprinkler offering to suit your project needs.

EXPLORE OUR OFFERING

SYSTEM DESIGN

Find the right Victaulic products or platforms for your project and build your submittal document package in real time.

VIEW PRODUCT GUIDE

CAREERS

We have what you are looking for - opportunity, growth and a collaborative work environment.

VIEW CURRENT OPENINGS

VICTAULIC MOBILE

Visit the all-new victaulicmobile.com app suite to access a whole world of mobile experiences including guides, configurators, and more!

VIEW VICTAULIC MOBILE

System Solutions

Our individual products blend seamlessly into application-based systems, enabling you to construct piping systems at any scale.

LEARN MORE